3D Printing a Holiday Ornament

Ben Travis, Former Marketing Manager

Article Categories:

Posted on

How did we bring a holiday gift idea to life with a 3D printer?

At Viget we have a 15-year tradition of creating a useful, creative, or sometimes just wacky holiday gift in the month of December. This year, we used our 3D printer and hardware skills to transform the Viget logo from a 2D design to a 3D object, and created one hundred Vigornaments to brighten up the season. The final product consisted of a custom-printed circuit board, nostalgic packaging, and two 3D-printed orbs that pay homage to the Viget logo.

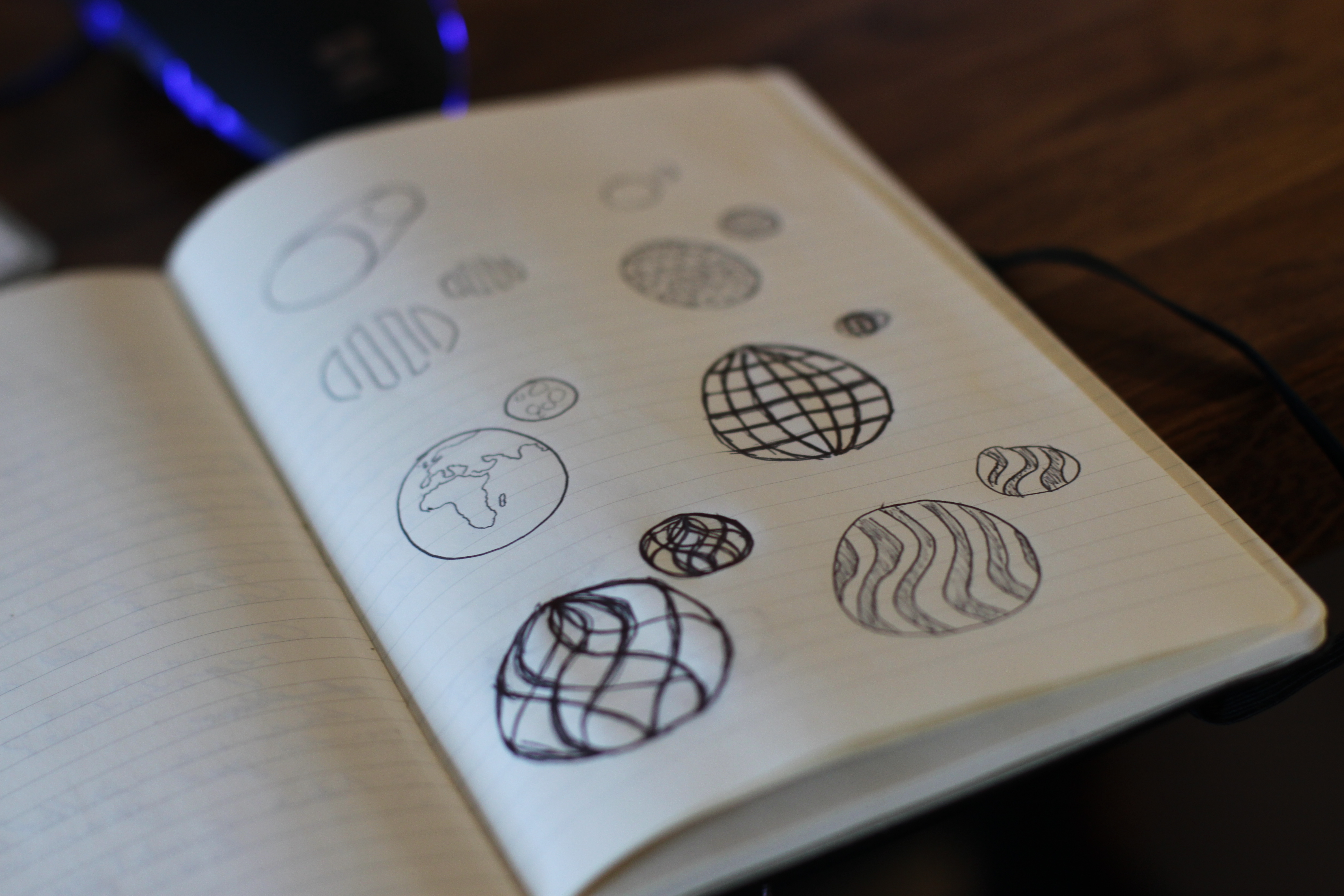

We started the project with a simple sketch, and then asked, “How do we design and mass-produce these 3D-printed orbs?” Ok, so two hundred orbs might not exactly qualify for mass production, but...

Designing and Testing

I began sketching a few different designs based on our logo, while also keeping in mind size and feasibility. We were working on a tight deadline and had to print all of our orbs in a limited timeframe, using a reasonable amount of material. I also looked for some inspiration on Thingiverse, an open community for sharing hardware designs.

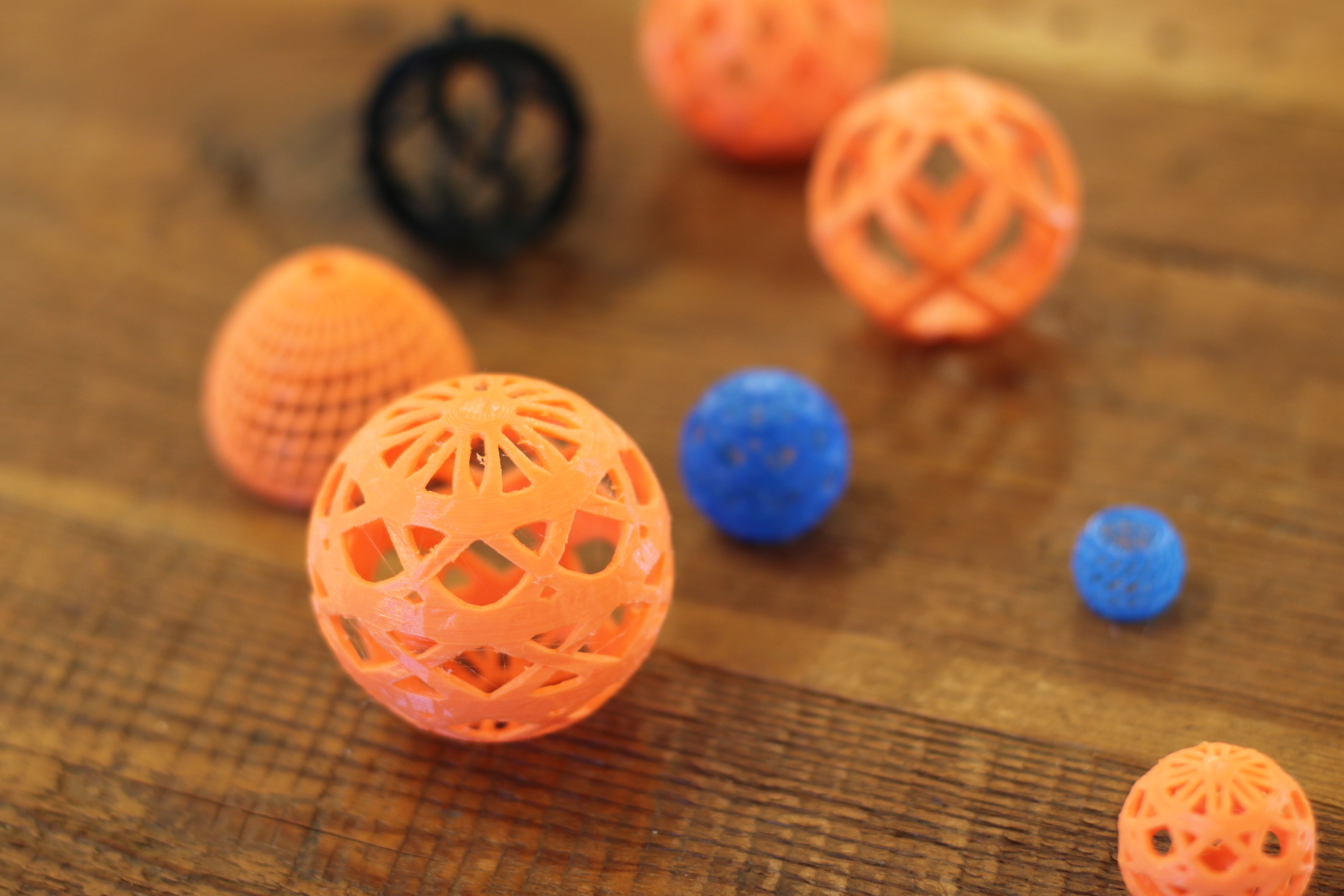

Having little 3D printing experience, I started learning about CAD software and designed orbs in multiple shapes and sizes. Blender was my primary design tool, which has the added bonus of costing exactly $0. After a fruitful period of trial and error (and some fun drop tests), we found our winning design. Next, I compared PLA and ABS as potential filaments and ultimately chose PLA since it’s a compostable bioplastic that doesn’t spew nasty fumes.

Printing and Cleaning

After locking down the the design and material, we jumped into production mode. With roughly a fortnight to print all orbs (barring any major disasters), we were looking at 110 hours of actual printing time. With our sole LulzBot Mini, we printed two or three times a day, with each batch taking around 7 hours to complete.

Fun fact: When printing multiple objects on a 3D printer, “wisps and hairs” become very apparent. After receiving my first plastic splinter, I turned to our Dremel for help, using it to file down all sharp protrusions. Spotify was a huge help...

Assembly

Along with plenty of other Vigets, I put together the final product, combining the PCB and electronic components with the 3D-printed orbs and small caps to ensure the LEDs were kept in place. With all components assembled, a flip of a switch brought our holiday project to life. Check out the video below to get a behind-the-scenes view: